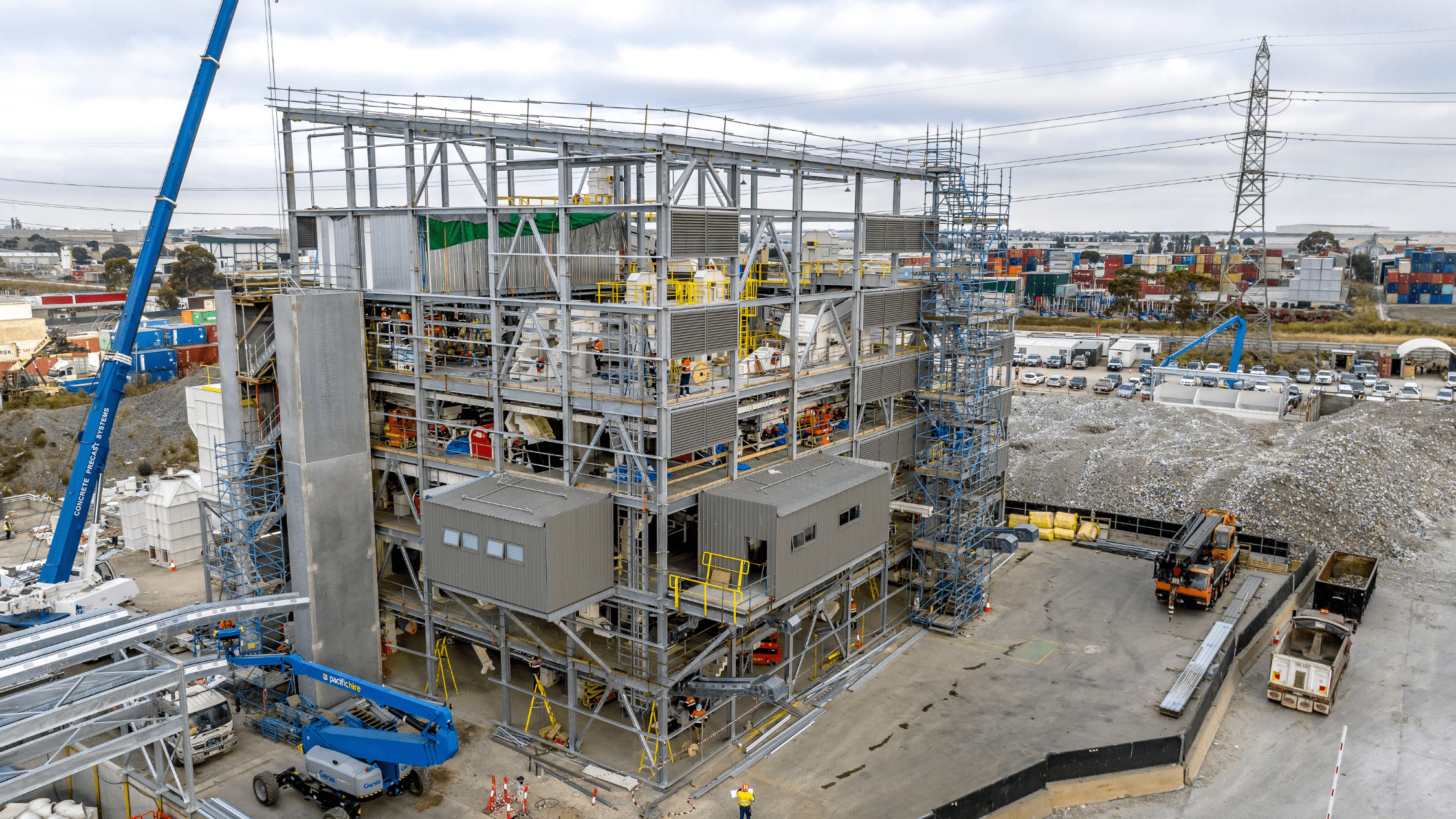

Projects and investments Laverton glass beneficiation plant

Recovering more glass through sorting and processing to remanufacture it into new bottles—again and again

We've invested in a new state-of-the-art cullet plant at our site in Laverton, Melbourne’s west.

Our cullet plant currently operates by sorting glass 10 millimetres in size or larger. Once the upgrade is complete—using 20 optical sorters—the facility will be able to sort glass down to three millimetres in size—boosting recycling and diverting more glass from landfill.

The facility will remove non-glass materials, sizes and sorts the remaining glass by colour for remanufacture into new bottles and jars.

It will be able to process 40 tonnes of glass per hour—up to 200,000 tonnes of glass per year, producing glass cullet that will go into Visy’s glass container making furnace down the road in Spotswood.

The upgrade gives us the capacity to recycle all of Victoria's glass and help us increase the average recycled glass content used by our glass manufacturing plants to 70%. By recovering and reusing more recycled glass in our containers we are reducing the amount of energy and emissions required to produce them.

The upgrade supports 92 jobs during construction and a further six ongoing positions once completed.

Project milestones

Official opening

15 February 2024 | Today we unveiled a major $50 million upgrade to our glass recycling factory in Laverton, Melbourne.

Construction update

8 August 2023 | We’re making progress on our glass beneficiation plant at Laverton in Melbourne’s west.

Announcement

15 April 2021 | We're building a state of the art $35 million glass recycling cullet facility in Laverton in Melbourne’s west.